Product Introduction

Metal processing cannot do without the cooling and lubrication of cutting fluids, but cutting fluids are easily

contaminated by guide oils and particles, which brings about the following problems:

1. A lot of downtime caused by waste liquid disposal;

2. Particles damage the processing accuracy of the workpiece, and the yield rate decreases;

3. Microparticles cause serious tool sticking and tool loss;

4. Floating oil produces a lot of oil mist during processing, and the workshop environment is poor;

5. Cutting fluid deterioration causes expensive pollution control costs;

6. Bacteria in the water cause allergies and other skin diseases in workers, etc.

The use of cutting fluid purifier can quickly and efficiently solve the problems of cutting fluid odor, impurities,

floating oil, mold, etc., realize the purification and recycling of cutting fluid and extend its service life.

Product Display

Application cases

1. Liquid storage tanks for various CNC machine tools, machining centers, and cleaning equipment.

2. Oily wastewater pools, such as repair shops, hardware processing plants, etc.

3. Coolant circulation reservoirs, such as cleaning machinery, equipment degreasing tanks, etc.

4. Pretreatment pools before wastewater treatment, such as electroplating wastewater, printing and

dyeing wastewater, etc.

5. Floating oil recovery before the flotation separation tank, such as catering oil separators.

6. Separation of two liquids with different specific gravities.

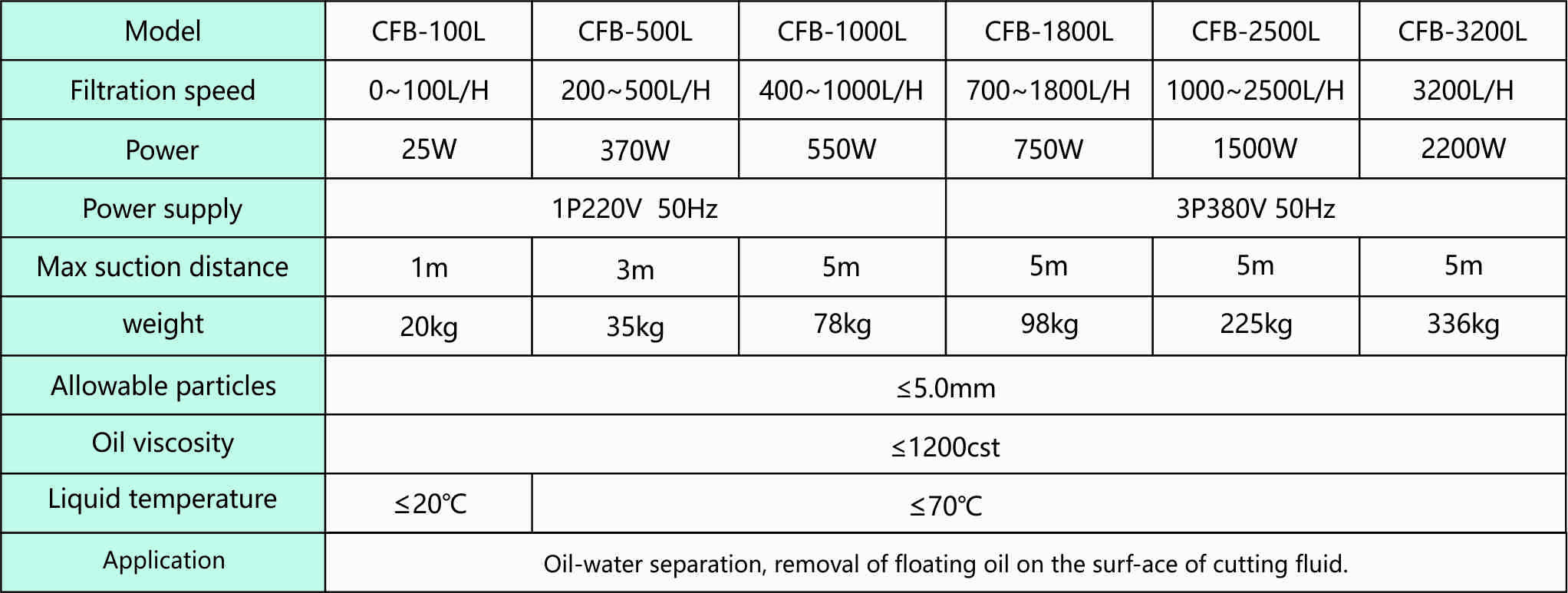

Product specifications

Contact: Eric Tang

Phone: +8615889784604

Tel: 0086-28-88414061

Email: erictang@chungho-tech.com

Add: 177 Beiquan Road, Longquanyi District, Chengdu, Sichuan ,China